Description

https://www.zhonggongtemetal.com/Hastelloy-C-22-Alloy-Pipe-Tube.html

● Delivery: within 10-15 days or considering the quantity

● Transport: By bulk or Containers;

● Supply ability: 3000 metric tons/ month;

● Payment terms L/C, T/T;

● It can pack by container or bulk vessel.

● Standard export seaworthy package, it use steel belt with bundle according product's size.

● We can make it as your requirement.

Hastelloy C-22 (UNS N06022) Super Corrosion Resistant Compound

Zhonggongte Metallurgical provides premium hastelloy c22 pipe and hastelloy C22 alloy tube products designed for the most aggressive and demanding applications in chemical processing, environmental protection, high-purity fluid systems, and metallurgical industries.

Hastelloy C-22 (UNS N06022) is a nickel-chromium-molybdenum-tungsten super-corrosion-resistant alloy with extremely stable chemical composition, superior mechanical properties, and excellent resistance to both oxidizing and reducing media.

These features make our tubing and piping components ideal for long-term stability in harsh corrosion environments.

All technical foundations are based on original Haynes factory specifications, heat-treatment standards, mechanical performance benchmarks, and strict quality control protocols,ensuring that every hastelloy c22 pipe and hastelloy C22 alloy tube meets or exceeds the highest global standards.

The essential connection between brand and alloy

Hastelloy C-22 is a registered trademark of Haynes International Inc. of the United States for the UNS N06022 alloy. It has the same chemical composition and core performance as Inconel C22 (Special Metals brand), both belonging to the "nickel-chromium-molybdenum-tungsten super corrosion-resistant alloy". However, Haynes provides more detailed original factory process standards, quality control procedures and brand-specific technical support. The following content is based on Haynes original factory data (latest version in 2025).

Haynes Original Factory Core Technical Specifications

1. Chemical composition (Haynes QQ-N-286 compliant version)

|

element |

Haynes Original Range (by weight) |

Scope of General Standard (ASTM B575) |

Original factory control advantages |

|

Nickel (Ni) |

56.0-60.0 (balance) |

≥56.0 |

Narrow-range control ensures corrosion resistance stability |

|

Chromium (Cr) |

20.0-22.5 |

20.0-22.5 |

Deviation ≤ ±0.3%, better than the general standard ±0.5%. |

|

Molybdenum (Mo) |

12.5-14.5 |

12.5-14.5 |

Furnace-by-furnace spectral analysis to avoid component segregation. |

|

Tungsten (W) |

2.5-3.5 |

2.5-3.5 |

High-purity tungsten raw materials are used (purity ≥ 99.95%). |

|

Iron (Fe) |

2.0-6.0 |

≤6.0 |

Controlling it between 2.0% and 4.0% improves processability. |

|

Carbon (C) |

≤0.015 |

≤0.015 |

Vacuum melting control, ≤0.010% (common) |

|

Silicon (Si) |

≤0.08 |

≤0.08 |

≤0.05%, reducing oxide scale formation |

|

Phosphorus (P) / Sulfur (S) |

≤0.02/≤0.01 |

≤0.02/≤0.01 |

Sulfur ≤0.005%, improves hot workability |

2. Original manufacturer mechanical properties (solution state, Haynes TM-1001 standard)

|

Performance indicators |

Original factory minimum value |

Original factory typical value |

General standard minimum value |

Test conditions (Haynes exclusive) |

|

tensile strength |

690 MPa |

760 MPa |

690 MPa |

Room temperature, gauge length 50mm, round bar Φ12.7mm |

|

Yield strength (0.2% skew) |

275 MPa |

330 MPa |

275 MPa |

Same test conditions as above |

|

Elongation (50mm gauge length) |

40% |

48% |

40% |

Measurements were taken after fracture to exclude necking error. |

|

Impact toughness (Charpy V-type) |

60 J |

85 J |

No mandatory requirements |

-196℃ low-temperature impact, notch depth 2mm |

|

Brinell hardness |

≤220 HB |

195 HB |

≤220 HB |

Load capacity 3000kg, indenter diameter 10mm |

3. Original factory heat treatment process (Haynes HT-2005 specification)

|

Process steps |

Original factory parameters |

General standard parameters |

Original Manufacturer Control Points |

|

Solution treatment |

1065-1095℃, heat preservation for 1 hour/25mm |

1060-1100℃, keep warm for 1-2 hours |

Precise temperature control within ±5℃ prevents grain coarsening. |

|

Cooling method |

Water quenching (cooling rate > 80℃/s) |

Water quenching (cooling rate > 50℃/s) |

Specialized quenching tank ensures uniform cooling. |

|

Intermediate annealing (for processing) |

950-1000℃, keep warm for 30 minutes, air cooling |

No clear universal standard |

For cold-worked parts, eliminate work hardening |

|

Stress-relief annealing |

650-700℃, hold for 2 hours, then cool with the furnace. |

600-700℃, keep warm for 1-2 hours |

Used in welded components to prevent stress corrosion. |

Haynes Original Product Form and Specification Tolerances

1. Core product (Haynes original model)

|

Product Form |

Original model |

Specifications range |

Tolerance advantages (compared to common standards) |

|

Sheet/Strip |

Haynes 22® Plate |

Thickness 0.4-150mm, width 1000-4200mm |

Thickness tolerance ±0.15mm (3-5mm thick), better than the general ±0.25mm. |

|

Bar stock/forgings |

Haynes 22® Bar |

Diameter 6-600mm, length 1-8m |

Diameter tolerance grade H7 (≤50mm: ±0.015mm), superior to the general grade H8. |

|

Seamless tube |

Haynes 22® Tube |

OD 6-273mm, wall thickness 1-25mm |

Wall thickness tolerance ±5%, better than the general ±8%. |

|

welded pipe |

Haynes 22® Welded Tube |

OD 10-355mm, wall thickness 0.8-20mm |

Outer diameter tolerance ±0.3%, better than the general ±0.6%. |

|

welding wire |

Haynes 22® Welding Wire |

Diameter 0.8-3.2mm |

Diameter tolerance ±0.005mm ensures stable wire feeding. |

2. Original factory surface quality standard (Haynes SQ-100)

|

Product Form |

Surface condition |

Original factory quality requirements |

Detection method (dedicated process) |

|

Sheet/Strip |

2B (Cold Rolled) |

Ra≤0.4μm, no scratches or indentations |

Laser roughness tester + 100% AOI inspection |

|

bar stock |

Peeled |

The surface is free of oxide scale, and Ra ≤ 1.6 μm. |

Eddy current testing + visual inspection (20x magnifying glass) |

|

Pipes |

Pickling (AP) |

Inner wall Ra≤0.8μm, no foreign matter. |

Endoscopic examination + ball-passing test |

|

welding wire |

Bright state |

The surface is free of oil and oxidation, and Ra ≤ 0.2μm. |

Electropolishing + Fluorescence Detection |

Haynes Original Manufacturer Recommended Application Cases (2023-2025)

1. Chemical Industry (Certification Case)

• Chlorobenzene production reactor for chemical plants : Made of Haynes 22® sheet (20mm thick) welded together, resistant to corrosion from a mixture of hydrochloric acid and chlorine at 120℃. On-site welding technical support is provided by the original manufacturer. Service life is guaranteed to be ≥20 years.

• The leaching tank of a certain hydrometallurgical nickel smelting project uses Haynes 22® seamless tubing (OD 159mm × wall thickness 8mm) to transport sulfuric acid leaching solution containing Cl⁻ (30000ppm), and the original manufacturer provides a corrosion resistance life assessment report.

2. Environmental Protection Sector (FGD System Dedicated Solution)

• Flue gas desulfurization tower for coal-fired power plants : Haynes 22® welded pipe (OD 108mm × wall thickness 5mm) is used as the spray pipe to replace the original 316L stainless steel, solving the problem of crevice corrosion. The original manufacturer provides a salt spray test report (1500h rust-free).

• Waste incineration plant leachate treatment equipment : uses Haynes 22® bar stock to process pump impellers, which are resistant to high concentrations of Cl⁻ (50000ppm) + organic acid corrosion, and the original manufacturer provides material traceability certificates.

3. Semiconductor field (ultra-high purity applications)

• The etching solution delivery system of a TSMC wafer fab uses Haynes 22® seamless tubing (OD 25mm × wall thickness 3mm), with electropolished inner walls (Ra≤0.2μm), and the original manufacturer provides a metal ion dissolution test report (≤1ppb), conforming to SEMI F57 standards.

Haynes Original Packaging and Certification Standards

1. Original factory packaging (dedicated anti-corrosion solution)

|

Product Form |

Packaging |

Protective measures (Haynes exclusive) |

Applicable transportation scenarios |

|

Sheet/Strip |

Vacuum VCI membrane + plywood pallet |

Membrane thickness ≥ 0.15 mm, with built-in oxygen indicator. |

Sea/Air Freight (Tropical Regions) |

|

bar stock |

Rust-proof paper + steel strapping + plastic cap |

Apply Haynes' special rust inhibitor (HT-700) to both ends. |

Land transport / Sea transport |

|

Pipes |

Layered wooden crate + silicone plugs |

Haynes' special desiccant (moisture absorption rate ≥300%) is placed inside the box. |

Long-distance sea freight (≥30 days) |

|

welding wire |

Sealed aluminum foil bag + H-beam wheels |

Argon purging protection (purity ≥ 99.999%) |

Global Air Freight |

2. Original manufacturer certification documents (Haynes proprietary format)

• Core document : Haynes Certificate of Compliance (CoC), containing:

◦ Furnace number, heat treatment batch number, and product traceability code (unique identifier);

◦ Furnace-by-furnace chemical composition analysis (ICP-OES data);

◦ Mechanical performance test report (including original manufacturer's laboratory number);

◦ Corrosion resistance test report (ASTM G48/G28 original data);

• Special Certification :

◦ Aerospace: NADCAP heat treatment certification (Haynes laboratory number HL-2025);

◦ Nuclear power sector: ASME BPVC III certification (compliant with NB-23 standard);

◦ Food/Pharmaceutical: FDA approved (21 CFR Part 175.300).

Comparison of Hastelloy C-22 with other C-series alloys (Haynes original data)

|

Alloy type |

Key differences |

Corrosion resistance advantage scenarios |

Cost comparison (with Hastelloy C-22 as 100%) |

|

Hastelloy C-22 |

High Cr (20-22.5%) + High Mo (12.5-14.5%) |

Oxidizing media containing Cl⁻+ (such as FGD slurry) |

100% |

|

Hastelloy C-276 |

High Mo (15-17%) + No W |

Reducing media (such as hydrochloric acid) |

115% |

|

Hastelloy C-2000 |

High Ni (60-65%) + Low Fe (≤2%) |

Ultra-low concentration corrosive media (such as high-purity chemicals) |

130% |

|

Hastelloy C-4 |

Low C (≤0.01%) + No W |

Scenarios sensitive to intergranular corrosion (such as high-temperature organic acids) |

120% |

Key Points for Original Manufacturer Procurement and Verification

1. Authenticity verification : Check production information through the official website (to avoid counterfeit products);

2. Technical support : Provides direct contact with original equipment manufacturer (OEM) technical engineers (such as welding process optimization and corrosion life assessment).

3.Batch requirements : It is recommended to use products from the same furnace number for key equipment to ensure uniform performance;

4.After-sales guarantee : Sign a quality assurance agreement (usually a 10-year corrosion warranty for normal operating.

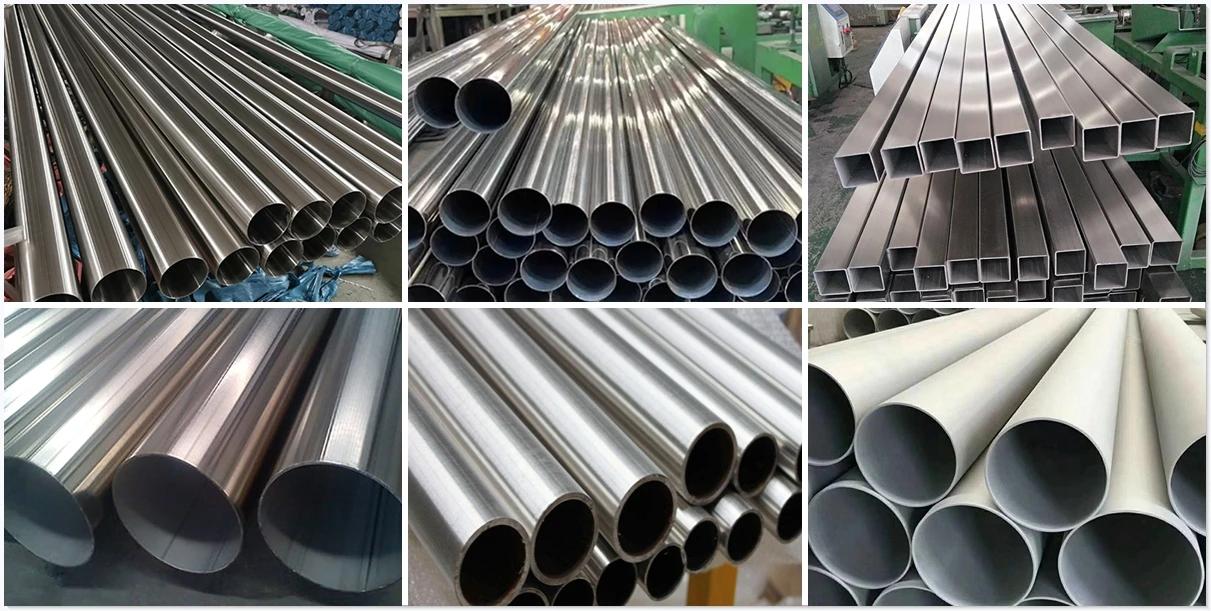

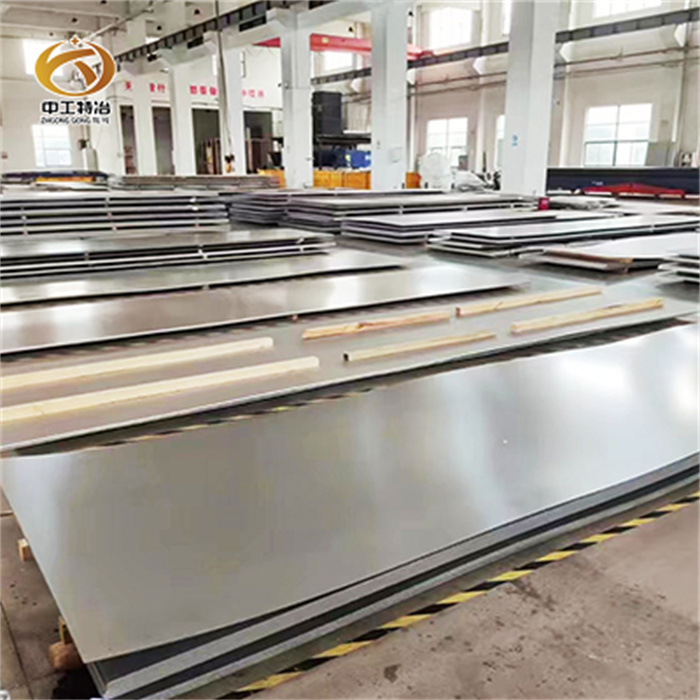

Product Display

Reviews

There are no reviews yet.