Description

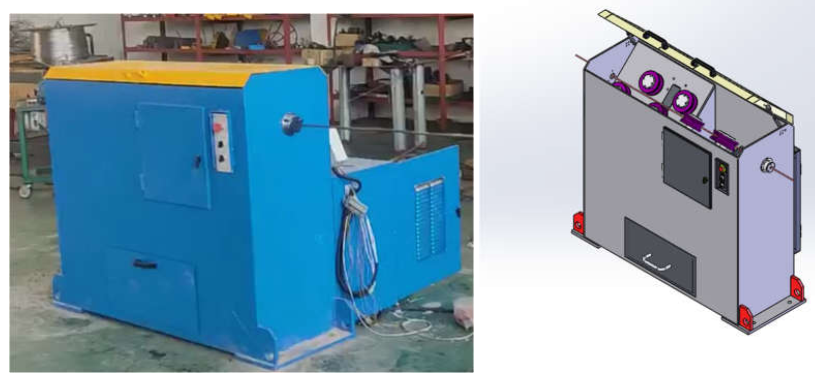

High carbon steel wire drawing machine

Straight line drawing machine for High carbon steel wire

SAE 1060, 1070 ,1080, 60#,62B,70#,72b,80#,82b, and son on

Used for Spring wire, mattress wire, PC wire, Prestressed steel bars, reinforced concrete steel wires and son on

Product line layout :

Pay off device → mechanical peeling remove oxide skin → Sand belt polishing→ boron coated → drying → straight line drawing machine→ tension adjustment device → Coil type or bobbin type take up machine

φ6.5mm→φ5.77mm→φ5.08mm→φ4.50mm→φ4.02mm→φ3.56mm→φ3.15mm→φ2.80mm→φ2.49mm→φ2.22mm→φ2.0mmMax working speed product 10~12m/s

High configuration: Japan control system, Siemens motor, Germany sensor,

Taiwan cylinder, All the same time, We have various types wire drawing

machine for different need, high quality more than good price,Meanwhile

investment cooperation in making galvanized wire machine, Annealing

furnace, nail making machine; include that electrical galvanized and

hot-dip machine, electrical power type and natural type power Annealing

furnace, high speed nail making machine

Parameter:

|

NO |

Capstan Dia(mm) |

300~400 |

500 |

600 |

700 |

800 |

900 |

1000 |

1200 |

|

1 |

Max.Iniet wire dia |

2.0~3.5mm |

3.0~4.2 mm |

5.0~5.5 mm |

6.0~6.5 mm |

6.5~7.5mm |

8.0~9.0mm |

9.0~11.0mm |

12.0~14.0 mm |

|

2 |

Min.Outlet wire dia |

0.35mm |

0.75mm |

1.0mm |

1.8mm |

2.4mm |

2.4mm |

3.5mm |

4.0mm |

|

3 |

Drawing passes |

7~10 |

6~12 |

6~12 |

5~12 |

6~9 |

3~9 |

6~10 |

6~10 |

|

4 |

Max speed |

10~12 m/s |

10~12 m/s |

10~12 m/s |

10 m/s |

10 m/s |

10 m/s |

10 m/s |

10 m/s |

|

5 |

Main motor power |

7.5-15 KW |

22-30 KW |

22-55 KW |

37 -75KW |

45-75KW |

45-75KW |

75-132KW |

110-160KW |

|

6 |

Max total wire reduction (%) |

94% |

94% |

94% |

94% |

94% |

94% |

94% |

94% |

|

7 |

Wire inlet strength |

≤ 1250 |

≤ 1250 |

≤ 1250 |

≤ 1250 |

≤ 1250 |

≤ 1250 |

≤ 1250 |

≤ 1250 |

|

8 |

Pay-off Type |

As customers requirement or according actual demand |

|||||||

|

9 |

Take-up Type |

Collecting in coil and bobbin |

|||||||

Main specification

1.Pay off machine Mode: Vertical Pay off Double station hydraulic type(Height Adjustable)

Used in :metal wire pay off, steel cord, wheel wire, wire rope, welding wire, stainless steel wire, umbrella wire, mesh wire, nails wire

2.Descaling Machine

The inlet end of the Peeling is provided with a carbide circular pass wire sleeve, which is hydraulically driven and consists of two sets of peeling wheels.

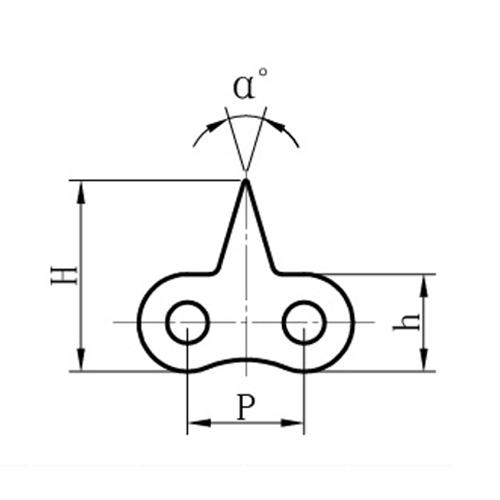

3.Straight line wire drawing machine

Mode: LZ9/700

Dies Match Scheme: Our engineer supply product process for reference or and customer supply

Inlet wireφ10mm—Outlet wire φ3.0mm

diameter Size φ700mm—9 blocks, height 340mm, tungsten carbide spraying height 100~120mm,

Hardness HRC 58 -60(surface spraying section- Spray tungsten carbide)

4. Bobbin take-up machine

Spool size: φ800mm (loading finished wire weight 800~1000kg )

wire diameter: φ3.0~4.0mm

Reviews

There are no reviews yet.