Description

The KPR enrichment system-KPR Zeolite Rotary Concentrator Processing process

This set of exhausted air purification equipment adopts advanced high air

volume tertiary filtration system + zeolite runner adsorption concentration +

desorption + high temperature incineration " process, using the principle of

large zeolite specific surface area and different molecular forces under

different temperature conditions. Under low temperature conditions, the organic

exhausted air through the zeolite molecular sieve wheel, VOC molecule adsorption

on its surface, after the exhausted air through the zeolite wheel can be

directly discharged. The zeolite wheel with a large number of VOC enters the

high temperature desorption area, using the high temperature clean air with

small air volume to desorattach the VOC molecules on the zeolite wheel, forming

a high concentration of waste gas, into the back end of the exhausted air

oxidation system thermal oxidation treatment, the purified exhausted air can be

directly discharged.

KPR Zeolite Rotary Concentrator Equipment Characteristics

1. The rotary runner is simple because of its simple structure

2. Can continuously concentrate the organic solvents

3 Suitable for the treatment of low concentration gale volume, low operating

cost

4. Use the hydrophobic molecular sieve as the runner adsorption material,

with non-combustible

5. Treat multiple solvents (Vocs) simultaneously

6. Can achieve 3-15 times of concentration, (according to different mining

conditions can be 20-30 times of concentration

7. Treatment air volume is 10000m3200000m3

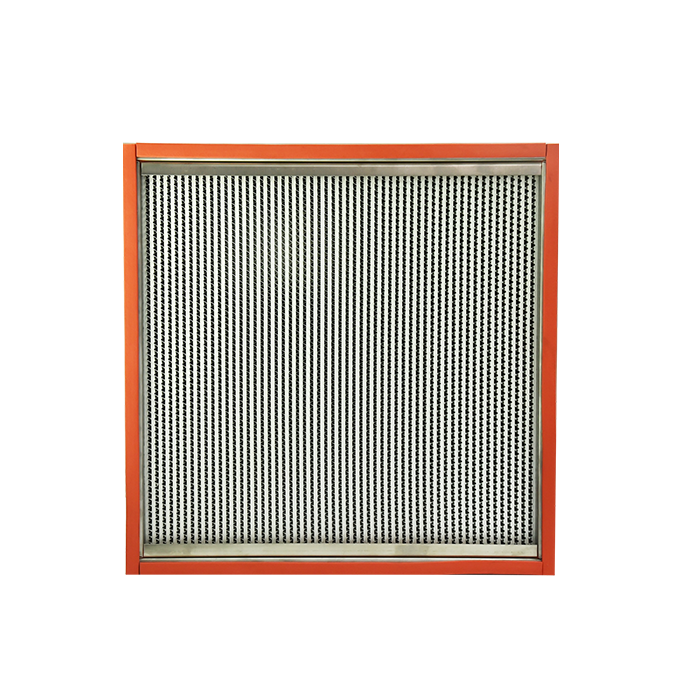

Level 3 filtration device

Function Introduction

1. Because the exhausted air contains oil fog and dust and other solid

particles, and the zeolite molecular sieve has strict requirements on the

content and particle size of the exhausted air, so the zeolite wheel is set

before: primary, medium and high three filters.

2. The filter material is composed of three-level medium and high efficiency

filter. The dust purification rate of 99% of more than 0.5um in the gas is

classified as modular design and convenient combination, installation and

disassembly, so that the equipment has good implementation.

Reviews

There are no reviews yet.