Description

Packaging: Pallet/Case

Productivity: 250 Sets/Month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 250 Sets/Month

Port: Shanghai

Payment Type: T/TIncoterm: FOB,CFR,CIF,EXW,FCA

-

Selling Units:Set/Sets

-

Package Type:Pallet/Case

-

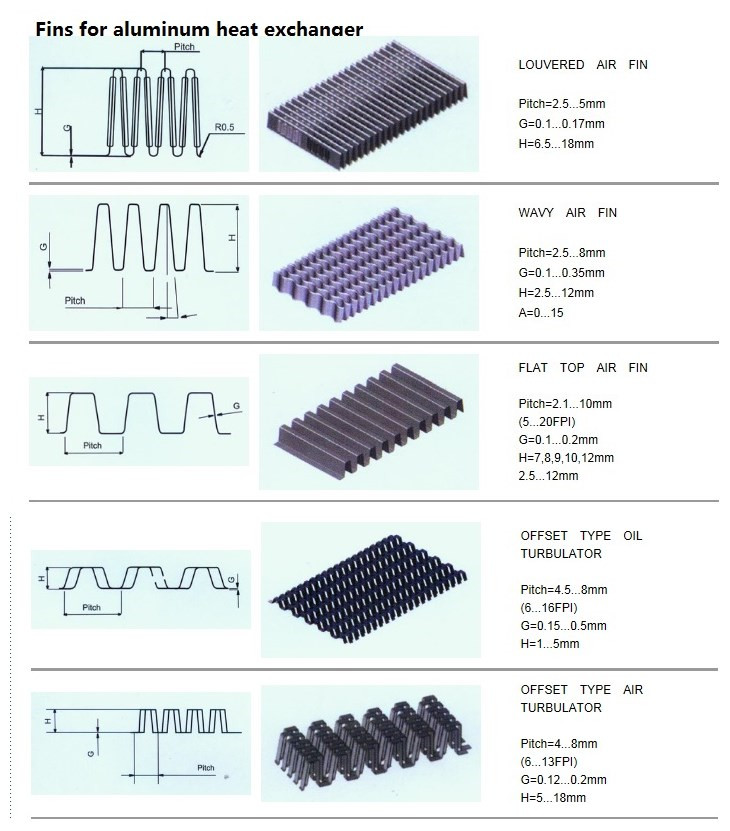

Fins are the basic components of heat exchanger, on which heat transfer to be finished depends. Main fin types: offset fin, straight fin, perforated fin, louvered fin, corrugated fin. High Speed Automatic Fin Forming Machine and Fin Molds is the special equipment to produce all kinds of Heat Exchanger Fins. With different fin molds, Heat Exchanger Fin production machine can automatically and stably produce all kinds of aluminum fins, Copper Fins and SS Fins. The fins via our fin forming machine have the advantages of high precision, good appearance and low processing cost. Heat exchanger fin production machine mainly include Automatic Feeding Material Device, High Speed Automatic Fin Forming Machine, Radiator Fin Forming Moulds, Automatic Fin Cutter/ Fin Servo Cutting Systemr. Better-Tech specializes in supplying the full set of fin forming solution. In the sereis of Fin Machine and fin molds, we uphold customized service to meet cllients' fin special design and demands. Please supply your fin specification or fin drawing, we can supply the optimized configuration to make you produce your desired heat exchanger fins.

-

Heat Exchanger Fin Type:

-

-

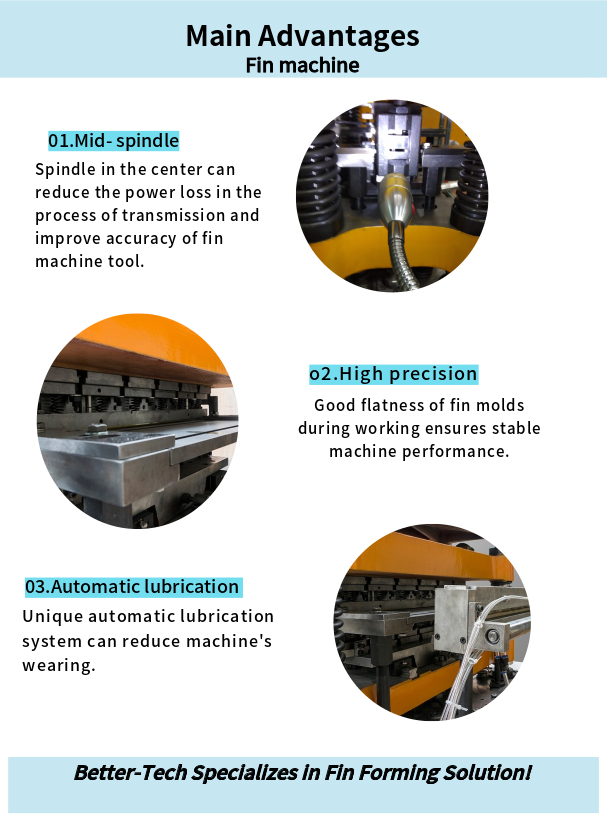

Better Tech Fin Machine's Advantages:

-

Reviews

There are no reviews yet.