Description

https://www.grinderprecision.com/CNC-automatic-ball-bearing-outer-ring-groove-grinder.html

3MK144 Machining accuracy

|

NO. |

Item |

Parameters |

|

1 |

Resiplus (including deformation error) mm |

0.12~08 (diameter direction) |

|

2 |

Processing Efficiency (on time grinding) |

From 8 to 10 seconds / piece |

|

3 |

Divergence ( mm) |

≤0.01 |

|

4 |

Ellipticity (2-15 waves) mm |

≤0.0018 |

|

5 |

Roundness (2 to 500) mm |

0.008 or outer diameter roundness + 0.0002 |

|

6 |

Groove Curvature Deviation mm |

≤0.015 |

|

7 |

Groove Shape Deviation (tested by Taylor instrument) mm |

≤0.002 |

|

8 |

Groove Position Deviation (same reference plan deviation) mm |

≤0.005 |

|

9 |

Groove Run Out (um) |

≤3 |

|

10 |

Wall Thickness Deviation |

≤0.003 |

|

11 |

Roughness (um) |

≤0.32 |

|

12 |

Wheel dressing Interval (piece / time) |

According to the field process requirements |

|

13 |

Surface Quality |

No burning defects, and the appearance meet the quality requirements |

Product characteristics and performance

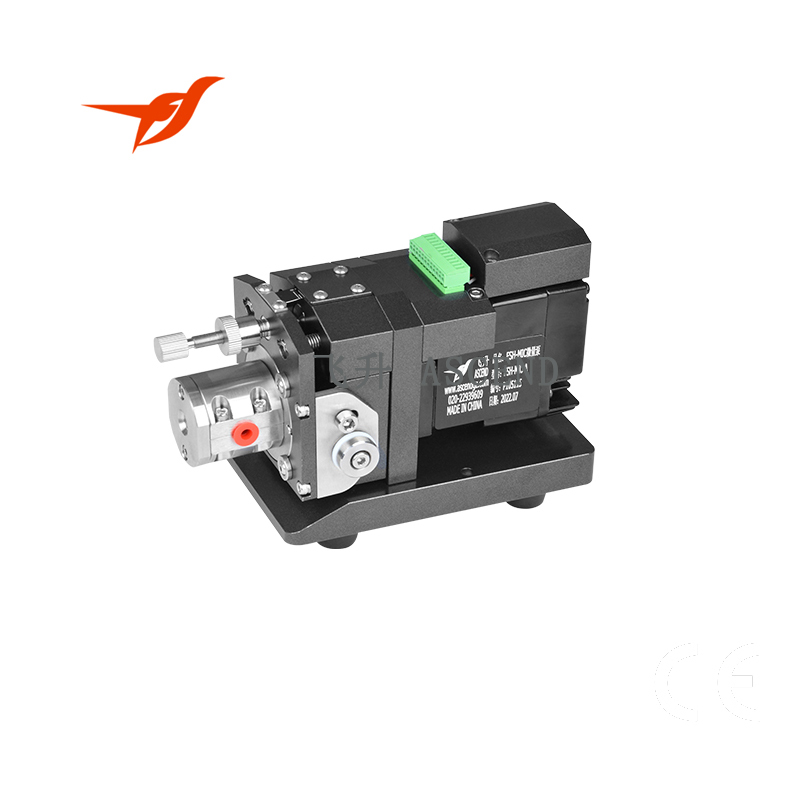

1. Grinder for ball bearing outer ring groove has small size,strong rigidity and high processing accuracy.

2. This grinder for ball bearing outerring groove's product size is dimensional discrete concentrated.The grinding smachine for ball bearing outer ring groove has perfect groove shape,roundness and curvature.This grinder for ball bearing outer ring groove can meet the accuracy requirements of motor bearings and high-precision bearings.

3. This grinding machine for ball bearing outer ring groove has adjustable control system resolution with 0.1μm and diamond disc rotary dressingwheel with perfect groove curvature and shape.

4. This grinder for ball bearing outer ring groove has stable and reliable optimal designed softwareand low failure rate.

5. This grinding machine for ball bearing outer ring groove has well-protected system.The grinder for ball bearing outer ring groove has no misoperation and misactionalmostly.

6. The self-diagnostic system of this grinder for ball bearing outer ring groove helpsthe operator solve problemsby text alarmconveniently.

7.Can set up passwords to protect parameterof this grinding machine for ball bearing outer ring groove and keep good process discipline and no accidents.

Other specifications

|

Machine Model |

Processing Range(mm) |

Working Accuracy |

Total Power (kw) |

Weight(kg) |

Overall Dimensions (cm) |

||

|

d |

b |

||||||

|

|

3MK146G |

26~72 |

9~20 |

Meet the accuracy requirements of P5 and P4 bearing rings |

22 |

3000 |

186×162×180 |

|

3MK1410G |

40~100 |

12~30 |

25 |

3500 |

203×190×183 |

||

|

3MK1420G |

80~200 |

25~80 |

25 |

4500 |

220×188×180 |

||

Reviews

There are no reviews yet.