Description

https://www.zdmt-machine.com/we67k-50t1500-small-cnc-press-brake.html

The model of this cnc press brake is ZDPE-5015 (WE67K-50/1500),with ZD-58 CNC control system, linear encoder, back gauge servo motors and other accessories of famous brand are installed for perfect machine performance.

Main Features

▪ Advanced proportional valve controls the hydraulic cylinders to work synchronously and achieve precise repeatability performance.

▪ Be capable of be controlled at random point within the stroke.

▪ Repeatability precision +/-0.01mm,parallelism precision +/-0.02mm.

▪ Deflection compensation table for high precision.

▪ ZD-58 CNC together with linear encoder, DP-TECH hydraulic system and other famous brand elements to ensure excellent performance.

▪ Quick clamps is for easy operation of removing and changing upper punch tools.

▪ X axis is controlled by servo motor,with strong synchronous belt,with high control accuracy,fast positioning and low noise.

▪ The backgauge installed with ball screw and linear rail,with high repetition accuracy and low maintenance.

Application

The application scope of press brake machine is very wide and they can be used in multiple industries and scenarios :

1. In the mechanical manufacturing industry, such as the processing of body panels in the automotive manufacturing industry;

2. Forming treatment used in the construction industry for manufacturing metal structural components such as railings and doors and windows;

On the electronic and electrical production line, it can be used for bending and shaping circuit boards as well as shaping and fixing coils, etc.

The production of various sheet metal parts in the hardware products industry also cannot do without the application of bending machines.

In fields such as aerospace, professional bending techniques are also required to process and shape special materials. In addition, bending machines can often be seen in some traditional industries such as light industry and textiles. In general, in any situation where thin metal sheets need to be bent, the application of a bending machine may be involved.

Main Specifications

| Model | 50/1500 | 70/2500 | 110/2500 | 110/3200 | 110/4000 | 130/3200 | 130/4000 |

| Bending force(KN) | 500 | 700 | 1100 | 1100 | 1100 | 1300 | 1300 |

| Bending length (mm) | 1500 | 2500 | 2500 | 3200 | 4000 | 3200 | 4000 |

| Columns distance (mm) | 1100 | 2050 | 1950 | 2650 | 3100 | 2650 | 3100 |

| Throat depth (mm) | 300 | 400 | 400 | 400 | 400 | 400 | 400 |

| Stroke (mm) | 150 | 170 | 200 | 200 | 200 | 200 | 200 |

| Open height (mm) | 340 | 360 | 385 | 385 | 385 | 385 | 385 |

| Main motor (kw) | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 11 | 11 |

| Dimensions (mm) | 2100x1700x2200 | 3100x1800x2360 | 3200x1800x2650 | 3800x2000x2650 | 4800x2000x2700 | 3900x2100x2670 | 4800x2100x2700 |

| Weight (kg) | 2000 | 4800 | 6200 | 7000 | 8000 | 7300 | 8200 |

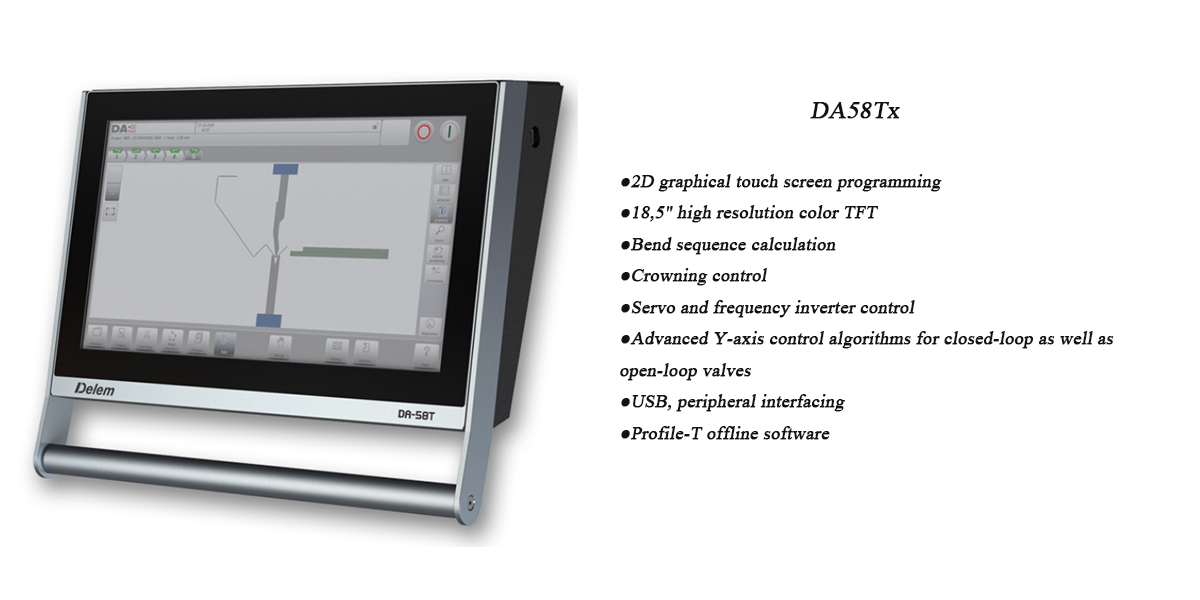

Optional control system

Company Profile

Reviews

There are no reviews yet.