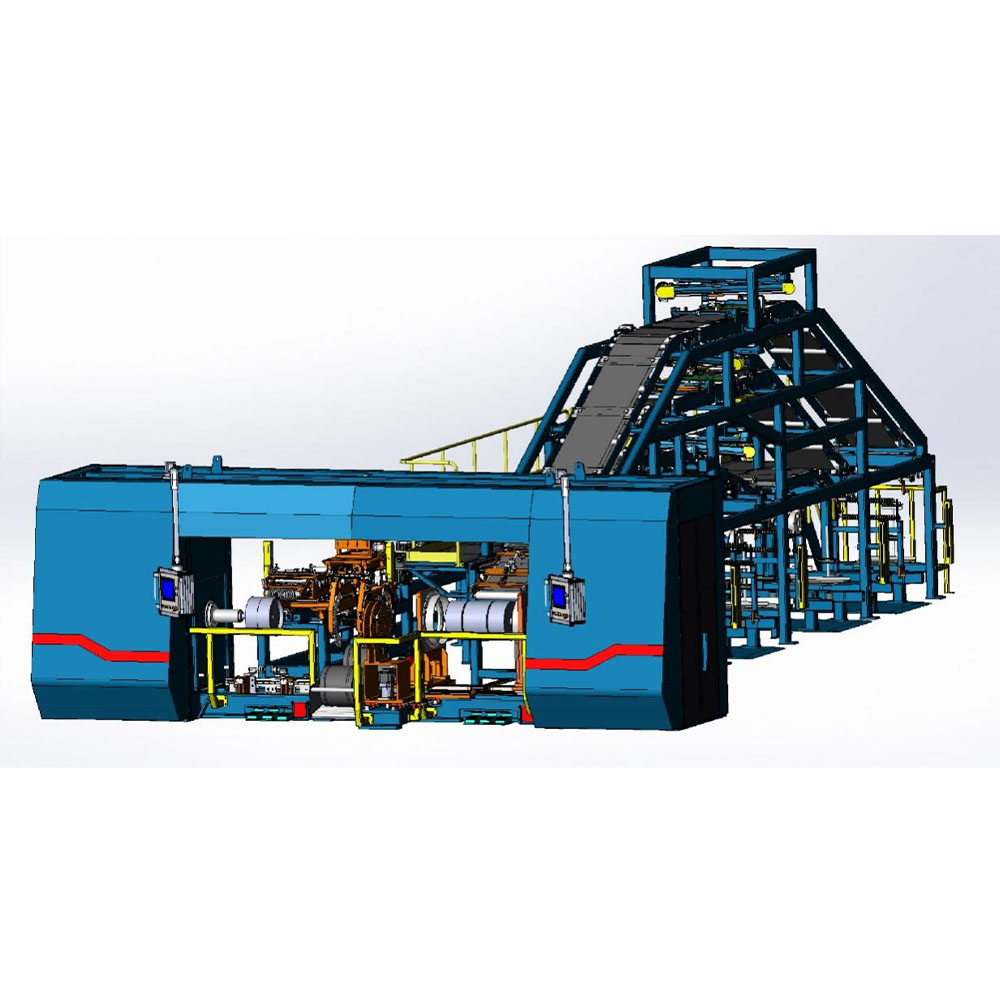

Description

Product Features:

High efficiency

-

Single cycle time 40s

-

Large roll I-shaped wheel

High quality

-

Integral welded mainframe

-

Ball-wrapped carcass drum

-

2-stage servo conveyor feeding to improve fixed length accuracy

-

Automatic fixed length and automatic cutting of each layer of material

-

Carcass joint detection (flash seam, wrong angle, big and small head, missing paste)

-

Ultrasonic cutter is used for tread, and the incision of the head and tail of the material is heated

High degree of automation and low labor intensity

-

Movable inner support wire placement seat

-

Automatic drum loading of steel wire ring

-

Automatic drum loading of carcass

-

Automatic tire unloading

-

Management of matching mode, one-button switching of specifications

High safety factor

-

Active safety rope, various photoelectric switch configurations

-

Anti-scalding and anti-pinch design

-

Upper and lower safety light curtains are configured on the operating side

-

Fault alarm prompt

Wide range of application

-

Applicable to the manufacture of motorcycle tires, agricultural tires and industrial special tires

Equipment Parameters:

|

Items |

Parameters |

|

|

Forming range |

14"-18" (08"-12", 12"-16") |

|

|

Equipment center height |

850-1000mm |

|

|

Rolling width |

0~350mm |

|

|

Rolling speed |

32.2mm/s |

|

|

Feeding form of tread, cord, liner |

Trolley type |

|

|

Lamination method of each layer of material |

Top mount type |

|

|

Inner rubber |

Width |

80mm-240mm |

|

Thickness |

0.4mm-1.4mm |

|

|

Cutting angle |

35° |

|

|

Cutting method |

Disc knife |

|

|

Curtain fabric |

Width |

150mm—380mm |

|

Thickness |

0.75mm-1.2mm |

|

|

Cutting angle |

24°—48° |

|

|

Cutting method |

Thermal cutting knife |

|

|

Buffer layer width |

50mm—240mm |

|

|

Tread rubber |

Width |

160mm—250mm |

|

Thickness |

5mm—15mm |

|

|

Cutting angle |

20°—30° |

|

|

Cutting method |

Ultrasonic cutter |

|

|

Overall efficiency |

≤40 seconds (liner × 1 + cord × 3 + tread × 1) |

|

|

Dimensions |

12000mm long × 6500mm wide × 3800mm high |

|

Equipment Accuracy:

|

Items |

Accuracy |

|

Levelness of guide rails of carcass drum |

≤ 0.05mm/m |

|

Radial runout of carcass drum main shaft |

≤ 0.1mm |

|

Axial runout of carcass drum main shaft |

≤ 0.1mm |

|

Radial runout of tread drum main shaft |

≤ 0.1mm |

|

Axial runout of tread drum main shaft |

≤ 0.1mm |

|

Coaxiality of carcass drum and tread drum |

≤ 0.5mm |

|

Coaxiality of carrying ring and tread drum |

≤ 0.5mm |

|

Coaxiality of carrying ring and carcass drum |

≤ 0.5mm |

|

Coaxiality of carrying ring and wire ring placement groove |

≤ 0.5mm |

|

Repeat positioning accuracy of carrying ring |

≤ ±0.2mm |

|

Inner rubber fixed length accuracy |

±2mm |

|

Inner rubber bonding accuracy |

±2mm |

|

Cord fixed length accuracy |

±2mm (Two yarns) |

|

Cord bonding accuracy |

3~5mm |

|

Cord single-side joint misalignment |

±3mm |

|

Tread fixed length accuracy |

±2mm |

|

Tread single-side joint deviation |

≤3mm |

Reviews

There are no reviews yet.