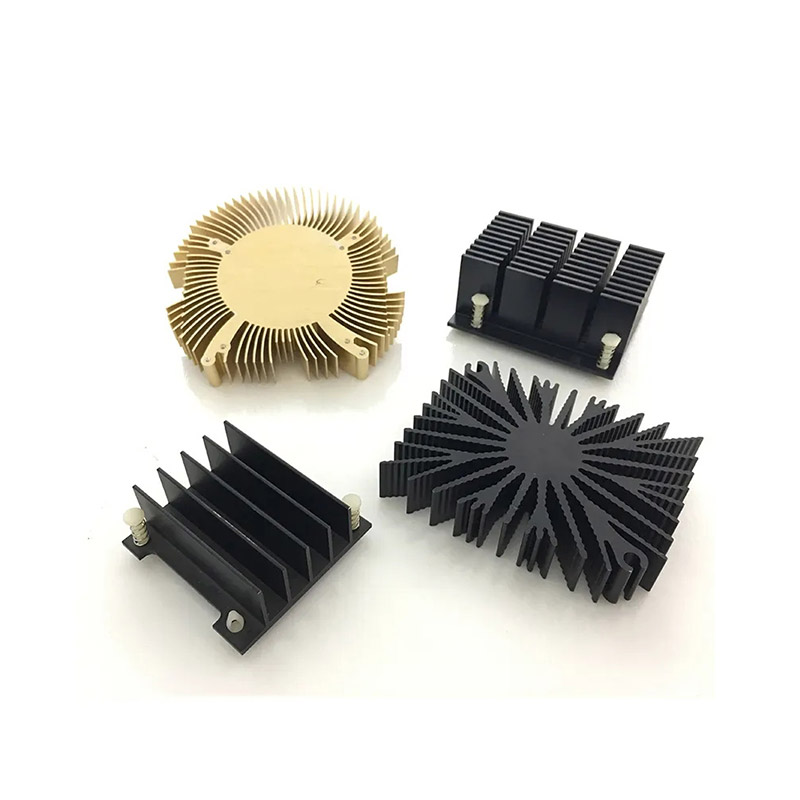

Description

Advantages of Anodized Heatsink Manufacturing

1.Enhanced Corrosion Resistance

Anodizing forms a protective oxide layer on the aluminum surface, significantly improving its resistance to corrosion and wear.

2.Improved Aesthetic Appeal

The process gives the heatsink a uniform, smooth, and visually appealing finish, which is crucial for products where appearance matters.

3.Increased Thermal Performance

The anodized layer can enhance the thermal conductivity of the aluminum, ensuring more efficient heat dissipation.

4.Durability

Anodized heatsinks are more durable and less prone to damage compared to raw aluminum, making them suitable for various environments.

Anodized Heatsink Manufacturing Process

1.Extrusion

Material Selection: Typically uses aluminum alloys like 6061 or 6063, which offer a good balance between cost and thermal conductivity.

Process: The aluminum billet is heated to around 500°C and forced through a die to create the desired finned profile. The extruded profile is then cooled and cut to the required length.

2.CNC Machining

Secondary Operations: After extrusion, the rough heatsink undergoes CNC machining to achieve precise features such as flatness milling, drilling/tapping for mounting holes, fin trimming, and surface milling.

Equipment: Utilizes CNC mills, lathes, or EDM for high-precision details.

3.Anodizing

Surface Preparation: The extruded and machined heatsink is cleaned to remove any oils or contaminants.

Anodizing Process: The heatsink is submerged in an electrolytic solution and an electric current is applied, forming an oxide layer on the surface.

Post-Treatment: The anodized heatsink is rinsed and sealed to enhance its durability and corrosion resistance.

Applications of Anodized Heatsink Manufacturing

1. Electronics

Ideal for cooling components in computers, servers, and GPUs, ensuring optimal performance and longevity.

2. Telecommunications

Used in base stations and other telecom equipment to manage heat effectively.

3. Automotive

Suitable for automotive electronics, where durability and thermal performance are critical.

4. Industrial Equipment

Applied in various industrial settings where reliable heat dissipation is required.

Comparison with Other Processes

|

Aspect |

Extrusion Only |

Extrusion + CNC Machining |

|

Cost |

Lowest |

Moderate (added machining cost) |

|

Design Freedom |

Limited to die profiles |

High (customizable features) |

|

Precision |

±0.2mm (typical) |

±0.05mm (critical surfaces) |

|

Lead Time |

Short (mass production) |

Longer (additional machining) |

Packaging and Shipping

FAQ

What is the purpose of anodizing a heatsink?

Anodizing enhances corrosion resistance, improves thermal performance, and provides a durable and aesthetically pleasing finish.

Can anodized heatsinks be customized?

Yes, anodized heatsinks can be customized through CNC machining to achieve specific features and dimensions.

Is anodizing environmentally friendly?

Modern anodizing processes are designed to be environmentally friendly, with proper waste treatment and minimal environmental impact.

How does anodizing affect the weight of the heatsink?

The added weight due to anodizing is negligible and does not significantly impact the overall weight of the heatsink.

In summary, anodized heatsink manufacturing combines the cost efficiency of extrusion with the precision of CNC machining and the enhanced properties of anodizing, making it an ideal choice for a wide range of applications.

Reviews

There are no reviews yet.