Description

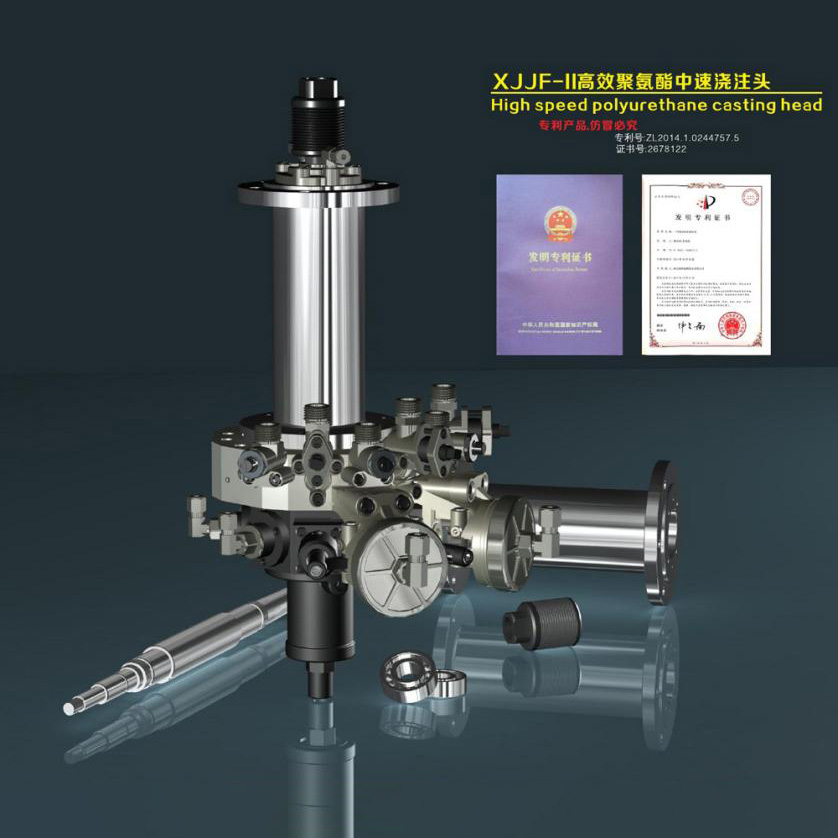

The low pressure mix head is designed with remarkable compactness in both size and weight. It is integrated with an electric motor, enabling it to operate at a rotational speed of approximately 8,600 rpm for efficient mixing. This mix head features a solvent and compressed air cleaning mechanism, which simplifies the maintenance process and ensures its cleanliness and durability. What's more, it has the functionality to allow additional compressed air to be injected into the mixing chamber, thereby significantly enhancing the mixing effect and contributing to the production of high-quality polyurethane products.

We offer a comprehensive range of mixers, each tailored to meet specific application requirements. These include mixers specialized for rigid low density foam production, which are ideal for applications where lightweight yet structurally sound foam is needed, such as in certain packaging or insulation scenarios. For applications demanding greater strength and density, like in construction materials, we have mixers for rigid high density foam. The HR flexible foam mixers are perfect for creating flexible foams that find their use in upholstery and cushioning applications, providing comfort and resilience. The integral skin foam mixers produce foams with a smooth and durable outer skin, commonly used in automotive interiors and consumer products for an aesthetically pleasing finish. Additionally, the elastomer foam mixers are designed specifically for manufacturing products like gaskets and shoe soles, where elasticity and durability are of utmost importance.

Note: The minimum and maximum outputs indicated in the accompanying table are based on the following specific chemical properties. However, it is important to understand that any variations in these properties, as well as other factors, will inevitably impact the actual output of the mix head. For customers with unique requirements, we also provide custom-made mixing heads upon request to ensure optimal performance for their specific applications.

Reviews

There are no reviews yet.