Description

https://www.xizi-ec.com/FHB206A-oil-buffer.html

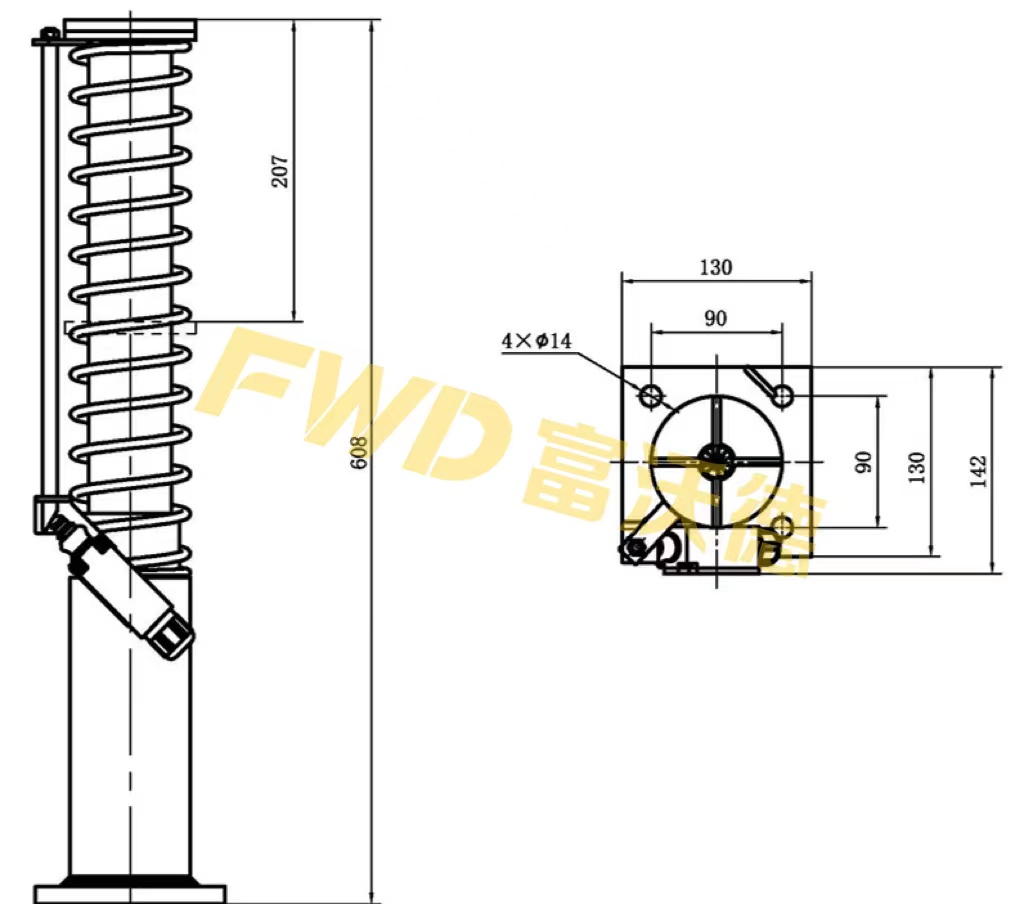

Type:FHB206A

Rated speed range(m/s):≤1.75

Rated load range(kg):600~3000

|

Mounting interface dimensions(mm) |

||||

|

Total height |

Buffer stroke |

Hole spacing A |

Hole spacing B |

Aperture diameter |

|

608 |

207 |

90 |

90 |

4×Ф14 |

Reviews

There are no reviews yet.