Description

https://www.josencnc.com/VMC-1266-CNC-Vertical-Machining-Center.html

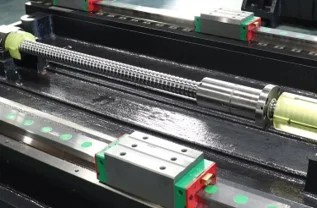

The machine is suitable for heavy cutting and precision machining in the fields of automobile and locomotive parts production, automation parts, mold and die frames, aerospace, etc. The three axes adopt high rigidity roller line rail with large span column, so that it has the heavy cutting rigidity and load bearing of hard rail machine, and at the same time has the high speed, high precision and long service life characteristics of line rail.

| ITEM |

UNIT |

DV-1266 |

DV-1266B |

| Travel |

| X-axis travel |

mm |

1200 |

1200 |

| Y-axis travel |

mm |

620 |

620 |

| Z-axis travel |

mm |

600 |

600 |

| Worktable size |

| Working table size (X*Y) |

mm |

1300×600 |

1300×600 |

| Max.loading capacity of working table |

kg |

1000 |

1000 |

| Table T-slot size (width * number of slots * spacing) |

number |

18x5x100 |

18x5x100 |

| Spindle |

| Spindle speed |

rpm |

10000 |

8000 |

| Spindle drive form |

|

belt driven |

belt driven |

| Spindle power |

kW |

BT40:11/15 |

BT50:15/18.5 |

| Spindle bore specification |

|

BT40 |

BT50 |

| Distance from spindle to table surface |

mm |

BT40:125-725 |

BT50:145-745 |

| Spindle feed |

| Rapid feed rate(X,Y,Z) |

m/min |

36/36/36 |

36/36/36 |

| Cutting feed rate |

mm/min |

10000 |

10000 |

| Tool magazine |

| Tool magazine capacity |

|

cutter arm type 24 |

cutter arm type 24 |

| Tool diameter/adjacent tool space |

mm |

BT40:Φ80/Φ150 |

BT50:Φ110/Φ200 |

| Max. Tool length |

mm |

300 |

300 |

| Max. Tool weight |

kg |

BT40:8 |

BT50:15 |

| Accuracy |

| Positioning accuracy |

mm |

±0.005 |

±0.005 |

| Reproduction accuracy |

mm |

±0.003 |

±0.003 |

| Others |

| Controller |

|

0i-MF/M80 |

0i-MF/M80 |

| Air pressure demand |

kg/cm2 |

6 |

6 |

| Power demand |

kVA |

30 |

30 |

| Machine weight |

T |

6.8 |

6.8 |

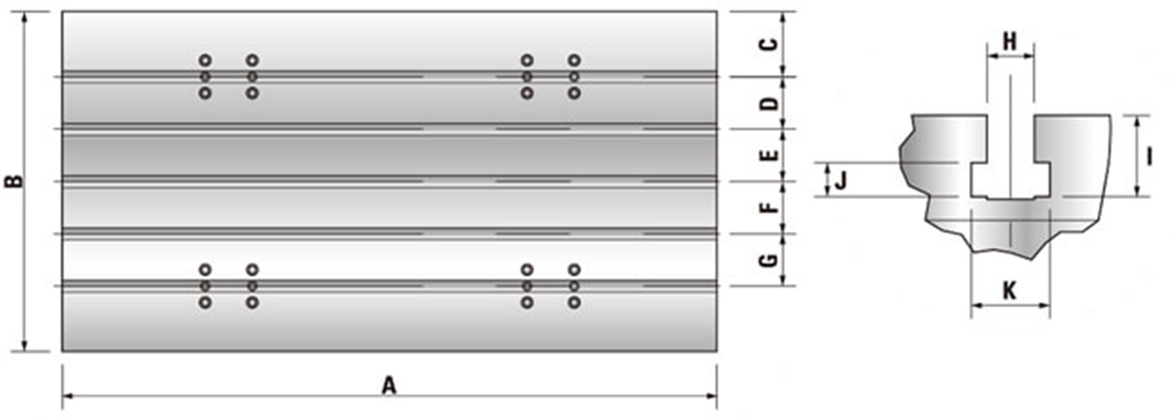

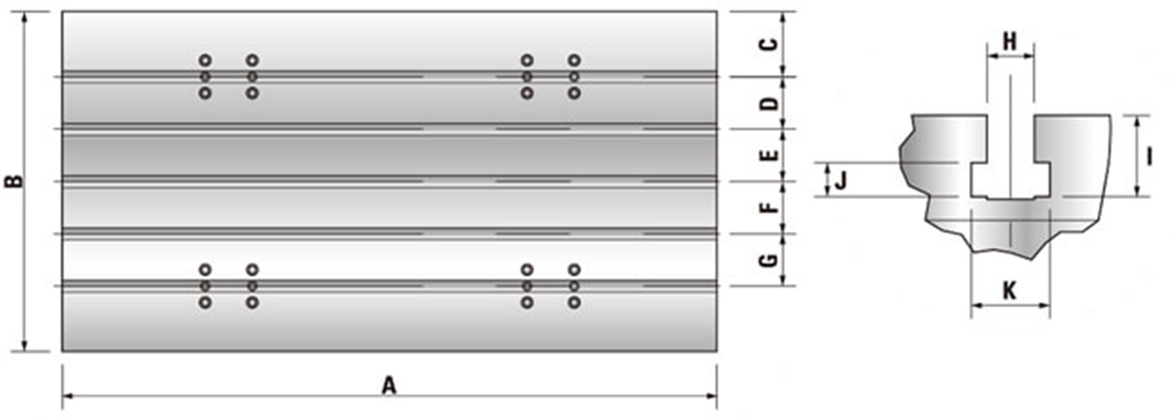

| Model |

A |

B |

C |

D |

E |

F |

G |

H |

I |

J |

K |

T-slot number |

| DV-1266 |

1300 |

600 |

100 |

100 |

100 |

100 |

100 |

18 |

31 |

13 |

30 |

5 |

| DV-1266B |

1300 |

600 |

100 |

100 |

100 |

100 |

100 |

18 |

31 |

13 |

30 |

5 |

|

|

|

|

|

|

|

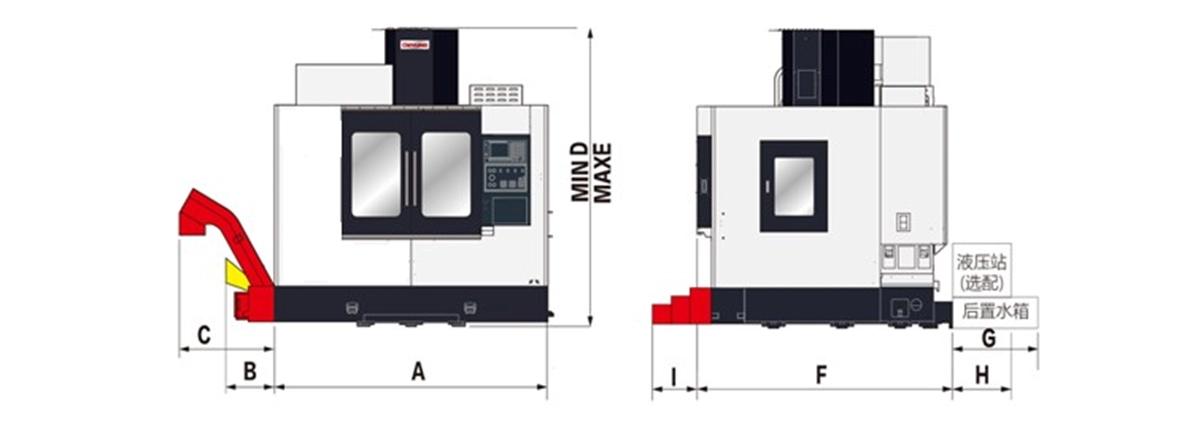

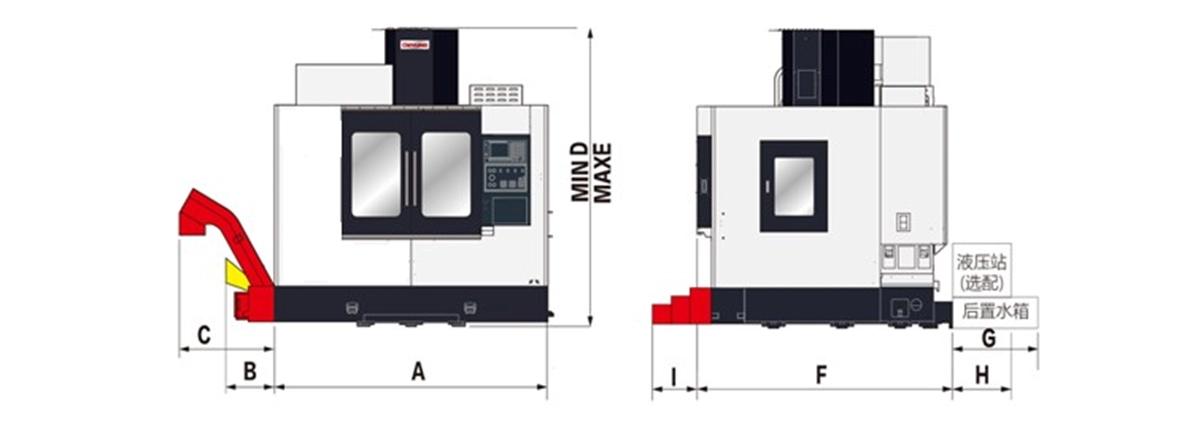

| Model |

A |

C |

D |

E |

F |

G |

H |

| DV-1166 |

2780 |

1450 |

2750 |

2865 |

2580 |

570 |

550 |

| DV-1166B |

2780 |

1450 |

2750 |

2865 |

2580 |

570 |

550 |

|

|

|

|

|

|

|

Reviews

There are no reviews yet.